Mastering Fine Material Classification with Eagle Iron Works and Southern Machinery

At Southern Machinery, we understand the importance of optimal fine material classification in your washing operations. That’s why we partner with industry leaders like Eagle Iron Works to bring you the best solutions for your needs. Eagle Iron Works’ Fine Material Washers are renowned for their exceptional classification capabilities.

The Power of Classification

Classification is at the heart of a Fine Material Washer’s function. By adjusting the height of the three overflow weirs, you control the amount of fine material that exits with the water. Keeping the weirs level minimizes the loss of product-size material, while lowering the back weir and raising the side weirs allows for the removal of excess fines. This level of precision gives you the power to tailor your classification to your specific product requirements.

Water Gallonage: The Key to Your Desired Mesh Split

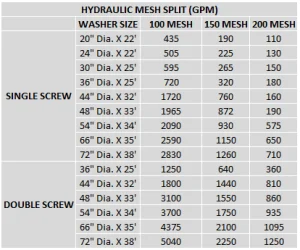

Managing water gallonage is crucial for achieving your ideal hydraulic mesh split. By increasing or decreasing the water flow, you can fine-tune your overflow to match your product specifications. Eagle Iron Works provides a handy slide chart to help you determine the optimal water gallonage for your Fine Material Washer. This invaluable tool simplifies the process of finding the perfect balance for your operation.

Unlocking the Power of the Eagle Iron Works Slide Chart

Eagle Iron Works’ slide chart is a powerful resource for optimizing your Fine Material Washer’s performance. This numerical table, complete with strategically placed cut-out windows, allows you to quickly determine the recommended water gallonage and screw speed for your specific machine size.

Determining Weir Overflow Gallonage and Hydraulic Mesh Split

To get the most out of your Fine Material Washer, it’s essential to determine the ideal weir overflow gallonage for your machine size and desired mesh split. The Eagle Iron Works slide chart makes this process simple:

- Measure the weir overflow depth using the slide chart’s built-in ruler.

- Align the slide with your measured weir depth to find the corresponding washer overflow in gallons per minute.

- Consult the chart on the right side of the slide rule to determine the approximate hydraulic mesh split. Eagle Iron Works recommends targeting the 150 mesh split point for optimal results in asphalt, concrete, mason sand, and golf sand production.

The Importance of Screw Speed

The Importance of Screw Speed

Screw speed plays a critical role in fine material classification. Slower speeds allow finer material to settle in the tub, resulting in a higher quality saleable product. The reverse side of the Eagle Iron Works slide chart helps you determine the recommended screw speed based on the percent passing the 50% mesh sieve.

Operating your Fine Material Washer at speeds faster than recommended can create excessive turbulence, leading to potential loss of product-size material. By using the slide chart to find the optimal screw speed, you can ensure maximum product retention and efficient washer operation.

Maximizing Product Retention with Rising Current Classifiers

Eagle Iron Works Fine Material Washers come equipped with Rising Current Classifiers to aid in the separation of damaging material from fine material. If you find you’re losing product-size fines with the overflow, consider turning off the Rising Current Classifier or reducing the water flow to the pool area. This simple adjustment can make a significant difference in your final product quality.

Trust Southern Machinery for Your Eagle Iron Works Needs

At Southern Machinery, we’re dedicated to helping you get the most out of your Eagle Iron Works Fine Material Washer. Our team of experts is always available to provide guidance on optimization and troubleshooting. Contact us today to learn more about how we can help you take your washing operations to the next level.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.com/lv/register-person?ref=SMUBFN5I

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.info/es-AR/register?ref=UT2YTZSU

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?